Category Archives: Equipment

I recently built a 2m groundplane antenna to be installed in my attic. Building an antenna is one thing, but getting it into the attic is another.

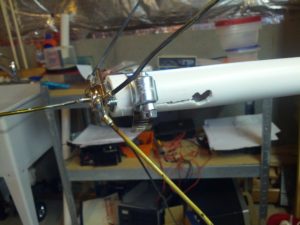

This is the lower mounting. Since this is in an attic, there is no need to be overly-worried about strength. There is no wind in the attic!

This is the slot that I used to be able to tighten the mast (which is just 3/4″ PVC) to the antenna connector.

Another view of the slot in the mast. Needless to say, this was the one I did SECOND, after I got a little more comfortable with the wannabee-Dremel router attachment.

Side note, after you take a rotary tool with a router blade to a piece of PVC pipe, you will have at least a million of these little shards everywhere.

This is a detail of the coax hole. I drilled an initial 3/8″ hole, and then used a 5/16″ bit to finish the angle.

This is the finished mount. I used a hose clamp around the collar to hold the antenna mount to the PL-259 attached to the antenna’s SO-239.

Several of us in the eastern Cincinnati area are getting HSMM-Mesh nodes up. The map below shows some stats – the blue are hams on tristatehams.org that have talked about it, the green are nodes that are believed to be up, and the yellow are locations that we have control over that we’ve talked about deploying future nodes.

View HSMM-Mesh Cincinnati in a larger map

Of course, given the distances we’re trying to do, my next few things to do involve some bigger antennas. Stay tuned, one of my future posts will be a better 2.4 antenna. I need lots of gain!

-73-

As part of my attic antenna plans, I built a 2m groundplane antenna. This will ultimately be for an iGate/packet station/digipeater (maybe). I did this with some fairly simple construction out of coat hangers.

The first thing I did was make sure the hanger pieces weren’t aluminum. I don’t have any aluminum solder, and I don’t plan to get any.

The second thing I did was solder lugs on the ends of the radials. This was, of course, after sanding the ends and brushing flux on them. This was also after taking a small blowtorch to the coating on some of the hangers.

Next, I tapped the screw holes in the PL-259 chassis connector. Once I did that, I attached the radials and soldered the middle.

Taking pictures of antennas is not easy!

The SWR at the high end of the 2m band is less than 1.2:1, the low end (around 144.39) is closer to 1.5:1. Both within the acceptable limit (for my radio) of 2:1.

-73-

Winter and it’s crummy weather has been in the air here in southwest Ohio (unless there was a heatwave when this went to post, I scheduled this one in advance).

I’m doing everything wrong, but I know I’m doing everything wrong so I know what to fix.

The first thing I’m doing wrong is a magnet mount. Mine’s damaging the paint below the magnet. While my truck is 10 years old, it is damn nice for being 10 years old, and I want it to last at least another 10. So the first thing I want to do is permanently mount an antenna to the truck.

The second thing I’m doing wrong isn’t really wrong. I have an FT-1900. I like it, but it is 2m only. I really could use 2m+70cm because some of the public service events I do use a 70cm “suitcase” repeater. Being able to hit that while driving can really help make my life easier. In addition, my main repeater has a cross-link on 70cm, so being able to monitor the cross-link frequency can be pretty useful to help fix problems. Having true dual receive would be great if the Skywarn net activates and I want to listen in on it while talking on my ‘normal’ repeater. Finally, having crossband repeat may sometimes be useful.

A third thing I want to do is start running APRS in my truck. I don’t know what solution I’m going to do, but I’m not going to do something with a lot of power – I’ll probably re-purpose an old HT to do this. But when I do that, I will still want an external antenna. That will also be something I turn on and off (yeah, sometimes I want to make sure I disappear!)

A fourth thing I want to do is run a permanent line for the antenna receptacle in the back of my truck. That receptacle is for hamsticks. I may also install my HTX-100 in my truck,

-73-

A few months ago I had the luck of winning a free PCB from Dangerous Prototypes via twitter. I finally got around to building it. Below are some pictures of the build. Please no comments on my soldering skills – I’m still a novice at SMD components. This is the second kit I’ve done with SMD components, and the other was only a handful of SMDs and mostly through-hole.

There is one part missing – I didn’t install the connector for the test leads. I forgot to buy it when I bought the rest of the components (and it wasn’t actually the only thing I forgot).

- The top of the board

- The bottom of the board

- The top while attached to an Uno. I did use different LED colors (green for power, and yellow for mode and voltage regulation).

This was a fun build, but it did underscore my need for a new soldering iron for SMD items and a new tip for my general purpose soldering iron (which is really too hot for SMD, but so far I haven’t burned anything up).

Now all I need to do is figure out how to use this thing! 🙂

-73-

I haven’t updated this in a while, not that there hasn’t been anything to update, it’s that I’ve been pretty busy.

In the past several months, I decided my trap vertical antenna in the backyard is a piece of shit. While operating in the 13 Colonies special event, I felt like I would have fared better yelling to people than using the radio. And playing some JT-65 after that made me think that the vertical is either sending everything straight up with no possible shot of reflection, or straight down in the ground. Not to mention, the guy behind me hates the thing. I think it pisses him off that he (not in my “community” can’t get the HOA to do anything about it. I haven’t been exactly secret about it’s existence, it is just that I don’t have a tower and a vertical hidden behind some trees isn’t in full view of my neighbors or the street. Well, except that guy, and he doesn’t count because he doesn’t pay into our neighborhood HOA. The HOA president has made it clear to me that the HOA will not get involved unless someone in the HOA has complained and nobody has.

My master plan was to finish a trap dipole antenna the weekend before the ARRL Sweepstakes and try to get on and at least make it half-way to a sweep. By finish, I mean that I’m going to build traps for 10, 15, 20, and 40 meters, tune the antenna, put it in the attic, and run cable down the ventilation shaft in the middle of the house.

So I learned a few things. One is that there is no way in Hell to do this without a good antenna analyzer. Another is that you should use the site that says “I constructed my traps using good quality RG-58/U coax scavenged from a discarded 10BASE-2 Ethernet cable.” should be used as guidelines. I don’t care how good quality of 10BASE-2 cable, no network administrator has used that shit since 1990!

Anyway, I found 100 feet of RG-58 to try this with (and at a damn good price). I realized almost immediately that this wasn’t going to work because damn good price is code for shit quality – the braid is aluminum. When I saw that, I immediately thought “WTF???” and tried to solder it just to make sure it wasn’t silver-colored copper or something else. Nope. Aluminum.

So I tried to make traps out of it using crimp connectors, which could have worked, but the crimp connectors don’t work too well on braid.

The following weekend was spent partially in Columbus for a meeting (on Saturday). Not being one to wake up at 4:30 AM for a long meeting, I went up on Friday and had even arranged another meeting at 2:30 in the afternoon. After that meeting, I dropped by Universal Radio and thought about buying some RG-58. Since they didn’t know if it was copper or aluminum braid, I bought RG-8X. With copper braid 🙂

Then came a weekend of winding traps. Ironically, this was on the weekend of the ARRL Sweepstakes. After having much difficulty, I found this awesome little piece of software by Tony Field, VE6YP. It is a coax trap calculator. Coax traps are a pain to make because the higher (than normal, or relative to most things a ham would build) Q. So after finding references to the capacitance per foot of “normal” RG-8X and inputting the other parameters, I found some combinations of PVC plumbing fittings and numbers of turns that would work. Of course the final traps I built, for 40 meters, were off, so I had to make a fix to those (and thank God I didn’t have to re-wind them, as I had run out of the coax I bought at Universal).

The following long weekend (Thanksgiving in the US) was spent with fixing turkey, pumpkin pie, and those 40 meter traps. I also tuned the antenna and hung it in the attic. That’s where I’m at. I tried to run the feed-line (that shitty RG-58 with the Aluminum braid, thanks to some crimp PL-259s). It’s stuck in the wall. I’m not sure how it is stuck, but I’m guessing there is a wire nest right between two sheets of OSB separated by the 2×8 flooring. Don’t ask me why there are two sheets of OSB. Normally there would be one on the top and nothing on the bottom (there’s drywall on the bottom of those same 2x8s where it’s above the living spaces, but there’s no need to have it below the floor in that area, especially with it being only a 2′ x 3′ space.

So I’m sitting here thinking “how do I get this damn wire down?” I really don’t want to pull it back and re-run it, but I may have to. I’ve been wondering if I can grab it with something, but it is 8 feet up the wall (guessing).

On the vertical, I think I’m going to leave it up for a while. It’s fuglier than sin, but since my neighbor supposedly (key word!) called the township who called the FCC a year ago but the only person to talk to me was our HOA president (the township zoning admin talked to the president and the HOA president told me all this), I’m not foolin’ with it. If they want me to do something, try talking to me. I’m not really a bad guy.

-73-

I am considering building a frequency counter. In part of that, I’ve been learning and playing around with logic chips. I started by playing with a few decade counters and setting those to count based on pulses from an Arduino. As I continued, I felt the Arduino was too slow and replaced it with a 555 timer used as an astable multivibrator and only used the Arduino as a power supply. Then, just to mess around, I put a photoresistor on it and used it to adjust the frequency. Below are the Fritzing image and a video showing how it works.

Since I’m not an electrical engineer and they teach nothing about oscilloscopes in traffic engineering classes, I’ve been viewing lots of videos about using scopes on YouTube. After seeing W2AEW’s video, I thought I’d get an Arduino and make a “poor man’s TDR” (as he calls it) by having the Arduino output pulses.

This is really quite simple. Too simple.

So simple it didn’t work.

Initially, it looked pretty good. I don’t know about the accuracy of the Arduino, but I imagine that it is good enough. The problem, I’m guessing, is the current. An Arduino is pretty limited (40 mA), so pushing it through a cable and expecting it to be able to act like the video might be pushing it.

Anyway, for the sake of showing, here’s what I did…

The Arduino Sketch

The Circuit

It’s pretty simple. Plug the scope probe into pin #7 and ground the scope probe ground to the Arduino.

The Results

Without any coax or with a ~6 foot piece of RG-58 open at the other end, I can see the step from the pulse. But when I connect a 50-ohm dummy load, the voltage drops.

Without a load:

With a load:

Note the difference in voltage between the two. I had the scope set to DC for these to keep the baseline the same, and the voltage per division was 1V.

Back to the drawing board.

-73-

This post is about the recently-built and the to-be-built projects I’ve been working on.

Recently Built: RF Sampler

First off, the recently-built. I recently built an RF Sampler. This little device allows me to connect a rig under test to my oscilloscope. The schematic is quite simple, as it is basically a voltage divider that divides the voltage between an internal resistor and a dummy load. Below are the pictures.

And what are pictures without a video to show it works?

The schematic for this is at http://www.qsl.net/k6ls/rfsampler.html. Also note this video from W2AEW (which is an expanded design of this).

Recently Built: Octopus Tester

Another item I recently built is an octopus component tester. This is a simple tester that makes some basic tests on electrical components, like capacitors. You can’t get the value of capacitance (etc) from this, but you can see if it works by hooking it up to the tester and checking it on an oscilloscope. I built this into an Altoids tin.

Below is what a capacitor looks like on the scope.

More information on this can be seen on W2AEW’s video.

In The Pipeline

I have one item in the pipeline, maybe two.

One of them is a Time Domain Reflectometer. There are schematics for that in the ARRL Handbook. This would help me test coax. I may jump to an Arduino-based pulse generator first.

-73-